Stirling Engine

Introduction

A Stirling engine is an engine that requires applied heat and uses a fixed amount of gas to run. It is considered a closed-system, which also makes this a very clean engine. The focus of this paper is the Gamma Stirling engine, as opposed to an Alpha or Beta type. Despite being of different types, they all run on the same thermodynamic properties since they are all Stirling engines.Stirling Engine Basics

A Stirling engine is an internal combustion engine but doesn’t require an explosion. A general Stirling engine has a piston cylinder and a crankshaft to generate mechanical motion. This motion is generated by air sealed inside of the engine, which expands when heated and condenses when it cools. Since it requires heat to expand the air and start the engine, the energy cycle is a thermal energy cycle. The relationship between temperature, pressure, and volume is explained in the next section and is the reason the engine operates. The pressure in the system pushes the power piston, which turns the crank and makes the flywheel rotate.

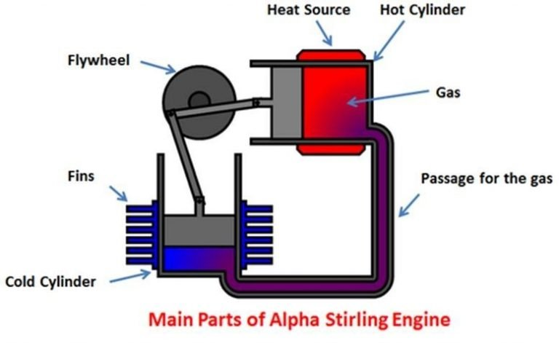

Figure 1 (Weber)

In Figure 1, an Alpha Stirling engine shows how a heat source expands the gas, which pushes the piston that turns the crank that makes the flywheel rotate. The momentum of the flywheel keeps the system moving while the gas contracts and the cycle starts again. The engine will start when there is a big enough temperature difference and will stop when this difference becomes too small. There are many different types of Stirling engines because of that fact, including ones that run on the warmth of your hand.

Figure 2 (Van Arsdell)

Figure 2 is a photo of a Stirling engine that runs on the temperature difference between ice and the temperature of the room. All of these Stirling engines have a fixed amount of gas that never leaves the system. This means the engine doesn’t let out any potentially harmful gases, even though most use air as their gas. It is very clean compared to a diesel engine, which lets out carbon dioxide at least, making the Stirling engine environmentally friendly.

Thermodynamics

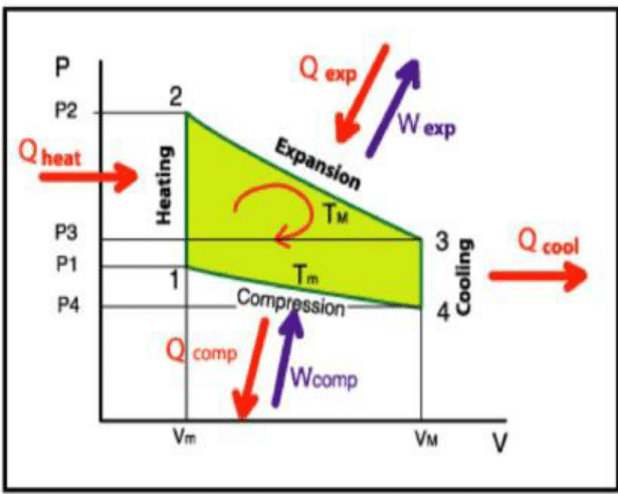

A closed-system is a system, in this case, that does not have a flow of mass in or out of the system. The Stirling engine has a fixed amount of gas that never leaves the system, it is only moved around the system. When considering the Stirling engine, it is important to remember several engineering concepts which play an important role in explaining how the engine works. Our specific Stirling engine, the Gamma model, can be characterized as four different categories.Figure 3 - Gamma Stirling Engine P-V Plot

The line from 1 to 2: Isothermal

Expansion(P=nRT÷V): Heat is radiated from flame to displacer piston. The volume of the gas is increased, while having a constant temperature. Work outputted from phase is equal to the heat transferred to the power piston. Stirling engine is not adiabatic.

The line from 2 to 3:

Isochoric Process: Heated fuel transfers temperature to heat exchanger and to walls. As a result, the pressure and temperature of the gas drops. With this phase in the thermodynamic process, volume is at its peak.The line from 3 to 4: Isothermal Compression

P=nRT÷V: When going through second isochoric process, gas that would have been cooled decreases overall volume and increases pressure.The line from 4 to 1:

Isochoric Process: After isothermal compression process, air flows back through heat exchanger chamber. Once again, heat causes temperature, pressure, and entropy to rise.The initial process that the stirling engine may be broken down is the isothermal compression and expansion, as well as isochoric process. The isothermal compression means there is a constant temperature, shown by the flame when assembling and making engine function. With the constant temperature, the change of volume at atmospheric pressure means the process is not only isothermal, but also isothermal compression. This is shown in the process between the movement of the piston from the top to the bottom of the assembly stroke. Work is done by the gas during the phase and a motion is caused from the crankshaft. With our specific stirling engine, the isothermal compression makes a full half stroke for its movement. The isothermal expansion is the increase in volume under constant temperature conditions. This can be shown with the pressure and volume diagram. Work is negatively done by gas, as it exerts energy to increase in volume. The concept is is shown by with the piston being on the side without the flame (increased temperature). This phase produces the largest pressure obtainable for the specific configuration, and represented when the displacer piston is moved from the bottom to the top of the assembly stroke. The last thermodynamic process is represented by the isochoric process which happens twice. In between the isothermal compression and expansion, the stirling engine is identified to be istochloric when volume does not change; and represented when the assembly configuration shows the piston is at the top of the engine’s stroke. The other phase for isochoric process is when the piston is moved back to strokes original position; and moved back to the cold side of our stirling engine’s assembly.

IV. Alpha vs. Beta vs. Gamma

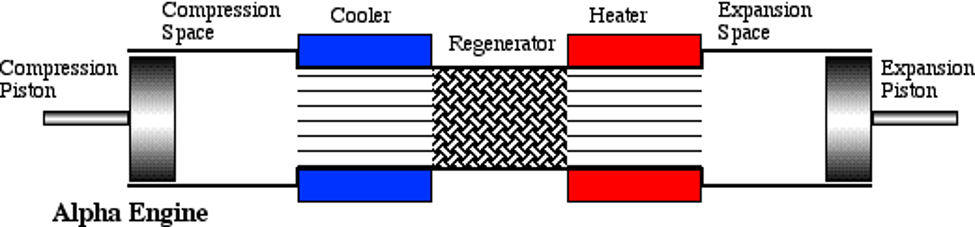

The Stirling engine’s mechanical makeup is, in general, separated into three groups: Alpha, Beta, and Gamma. To start off with, in general the Alpha engine has two pistons that are in separate cylinders, which are connected by a heater, regenerator, and cooler as shown in the figure below.

Figure 4 - The Alpha Engine’s configuration

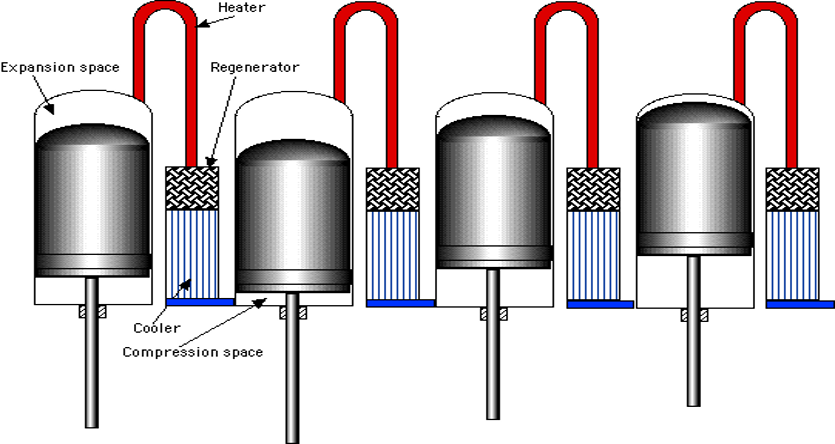

This type of engine can also be compounded into a multi-cylinder system, which allows a high specific power output as shown in the figure below. These multiple cylinders are interconnected; the expansion space of one cylinder is connected to the compression space of the adjacent cylinder through a connected heater, regenerator, and cooler.

Figure 5 - The multi-cylinder Alpha Engine

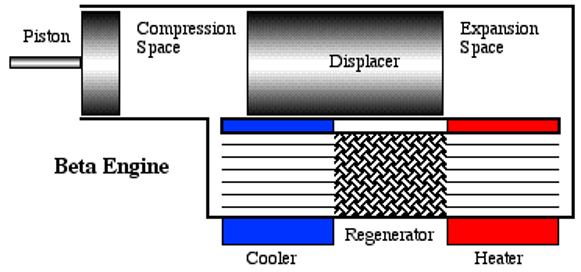

In contrast, the Beta engine has a singular piston and cylinder. These elements serve to displace the working gas at constant volume, and shuttle it between the expansion and compressions spaces through the cooler, regenerator, and heater. In actual engines, the link pushing the piston and the displacer will move both of them so that the gas will compress mainly within the cool compression area and will expand within the hot expansion area.

Figure 6 - The Beta Engine’s configuration

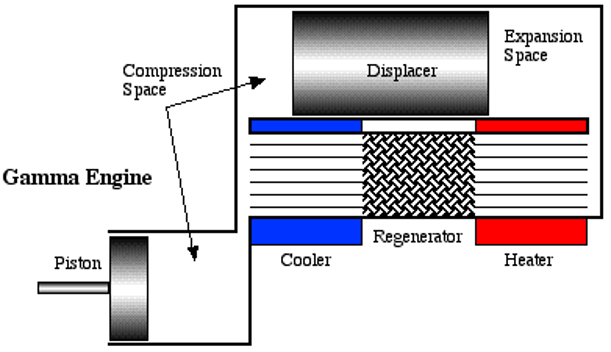

The Gamma type of engine also has a displacer and power piston like the Beta, but these elements are contained in a different cylinder. This facilitates a separation between the heat exchangers that work with the displacer cylinder and the compression and expansion work space associated with the piston. These types of engines tend to have large volumes that are untouched compared to their counterparts. The Gamma engine is often used when having the advantage of separate cylinders outweighs decreased amount of specific power that comes out in this process. Due to the convenient structure of the two cylinders, they provide independent sizing and construction of the displacer and piston assemblies, the gamma type of engine is very popular for recreational use.

Figure 7 - The Gamma Engine’s Configuration

V. Conclusion

The Stirling engine requires a temperature difference in order to run, and runs with a fixed amount of gas in its system. It is environmentally friendly because its lack of emitted substances, making it a clean engine. There are different types of Stirling engines, including Alpha, Beta, and Gamma types. They all run based on the same thermodynamic properties, which makes them very interesting and unique.References

Urieli, Israel. “Chapter 2a – Alpha Stirling Engines.” Stirling Engine Configurations , 30 Mar. 2013, www.ohio.edu/mechanical/stirling/engines/engines.html.

Urieli, Israel. “Chapter 2b - Beta Type Stirling Engines.” a Type Stirling Engines , 30 Dec. 2011, www.ohio.edu/mechanical/stirling/engines/beta.html.

Urieli, Israel. “Chapter 2c - Gamma Type Stirling Engines.” Gamma Type Stirling Engines , 26 Dec. 2011, www.ohio.edu/mechanical/stirling/engines/gamma.html.

Van Arsdell, Brent “How Stirling Engines Work.” American Stirling Company, 7 May 2018, https://www.stirlingengine.com/.

Weber, Marcus. “How Stirling Engines Work - MEEE Services: Mechanical Engineering.” MEEE, 6 July 2019, https://www.meee-services.com/how-stirling-engines-work/.